Introduction

Agriculture across the world is entering a phase where precision, sustainability, and resource efficiency are more important than tradition alone. One of the most significant shifts in modern farming has been the movement away from exclusive dependence on natural soil toward engineered growing media. Among all alternatives tested globally, cocopeat, derived from coconut husk, has emerged as one of the most reliable, scalable, and environmentally responsible solutions.

Cocopeat is no longer limited to home gardening or small nurseries. It is now widely used in commercial greenhouse operations, terrace farming systems, plant nurseries, vertical farms, and high-value vegetable and flower production units across Asia, Europe, the Middle East, and parts of North America.

This post is written for farmers, agri-entrepreneurs, researchers, and serious growers who want a clear, complete, and practical understanding of cocopeat from the ground level to advanced farming applications.

What Is Cocopeat?

Cocopeat, scientifically referred to as coconut coir pith, is the fine particulate material obtained as a byproduct during the extraction of coconut fibers from coconut husks. Unlike peat moss, which comes from slow-growing wetlands, cocopeat is derived from a renewable agricultural residue, making it environmentally sustainable.

It is composed mainly of:

Lignocellulosic fibers

Micro-porous organic particles

Stable carbon-rich compounds

Cocopeat does not decompose quickly, retains moisture exceptionally well, and provides high oxygen availability to plant roots when managed correctly.

Raw Material Source and Global Production

Coconut Husk as a Resource

Coconut-growing regions produce millions of tons of husk annually. Major cocopeat-producing countries include:

India

Sri Lanka

Indonesia

Philippines

Vietnam

In these regions, coconut husk was traditionally considered agricultural waste. Modern processing transformed it into a globally traded growing medium.

Manufacturing Overview

Cocopeat production involves:

Husk collection and aging

Crushing and fiber separation

Repeated washing to remove excess salts

Drying under controlled conditions

Screening by particle size

Compression or slab formation

Each step affects final quality, water retention, EC stability, and structural performance.

Physical Properties of Cocopeat

Water Holding Capacity

Cocopeat can retain five to eight times its own weight in water, allowing consistent moisture supply to crops.

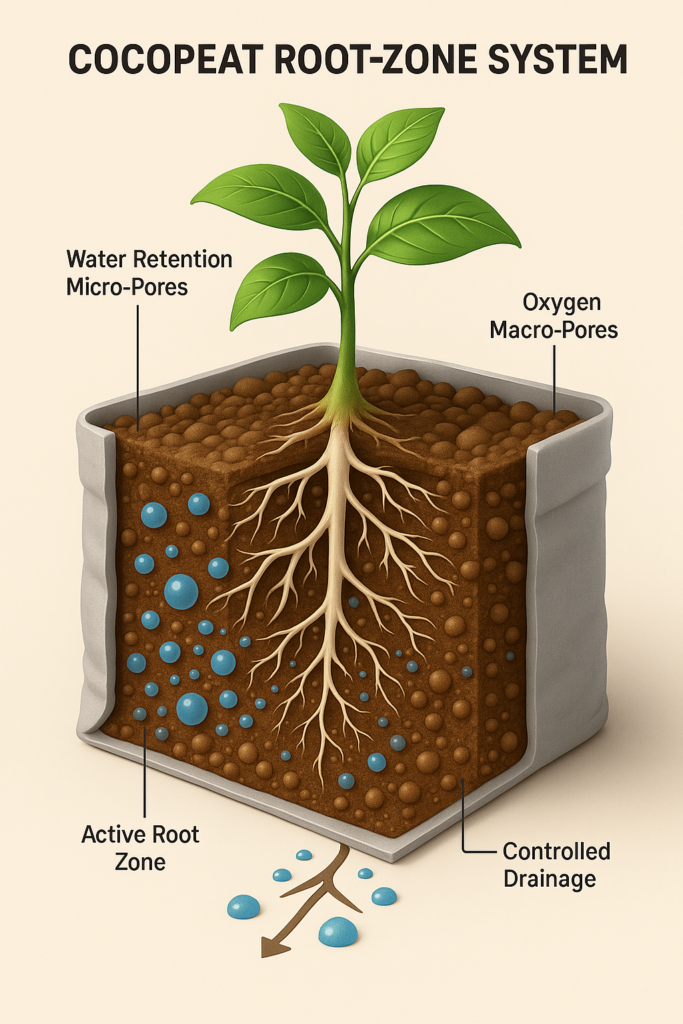

Porosity and Aeration

Its internal structure consists of macro- and micro-pores that:

Hold water in micro-pores

Maintain oxygen in macro-pores

This balance supports healthy root respiration and reduces anaerobic stress.

Bulk Density

Cocopeat is lightweight, reducing structural load on terraces, greenhouses, and vertical systems.

Chemical Properties of Cocopeat

pH Range

Typically ranges between 5.5 and 6.8, ideal for most horticultural crops.

Electrical Conductivity (EC)

High-quality cocopeat maintains EC below 0.6 mS/cm after proper washing and buffering.

Cation Exchange Capacity

Cocopeat has moderate cation exchange capacity, allowing it to:

Hold potassium naturally

Bind calcium and magnesium when buffered correctly

Without buffering, calcium and magnesium imbalance can occur.

Biological Characteristics

Cocopeat is:

Free from soil-borne pathogens when properly processed

Resistant to fungal buildup compared to organic soils

Biologically stable with slow microbial breakdown

This stability ensures consistent root environment across cropping cycles.

Why Cocopeat Is Preferred Over Soil in Modern Systems

Traditional soil farming faces challenges such as inconsistent texture, compaction, pathogen load, and nutrient variability. Cocopeat addresses these issues by offering:

Uniform structure

Predictable root-zone conditions

Easy nutrient management

Compatibility with fertigation

For high-value crops, cocopeat allows farmers to control growth variables with precision.

Applications of Cocopeat in Farming

Nursery and Seed Germination

Cocopeat ensures:

High germination rate

Uniform seedling growth

Easy transplanting with minimal root damage

Greenhouse and Polyhouse Cultivation

Widely used in grow bags and slabs for:

Tomatoes

Peppers

Cucumbers

Lettuce

Strawberries

Terrace and Urban Farming

Lightweight nature prevents structural stress and enables:

Container farming

Rooftop gardens

Modular grow systems

Hydroponic and Soilless Systems

Cocopeat acts as an inert support medium, allowing precise nutrient solution control.

Crop Suitability

Cocopeat is suitable for:

Leafy vegetables

Fruit vegetables

Herbs

Flowers

Nursery plants

It is not recommended for cereal crops or large-scale field farming without modification.

Nutrient Reality of Cocopeat

One of the most misunderstood aspects is nutrients.

Cocopeat:

Contains negligible nitrogen and phosphorus

Naturally high in potassium

Requires external nutrient supplementation

Successful cocopeat farming depends on:

Balanced nutrient solution

Proper fertigation schedule

Monitoring pH and EC

Without nutrients, plants will survive briefly but fail to produce economically.

Cocopeat Buffering Explained

Unbuffered cocopeat binds calcium and magnesium aggressively, causing deficiency symptoms. Buffering involves:

Treating cocopeat with calcium nitrate or calcium chloride

Replacing excess sodium and potassium

Stabilizing root-zone chemistry

Buffered cocopeat ensures long-term nutrient availability.

Cocopeat Reuse and Lifecycle

Cocopeat can be reused for two to three crop cycles when:

Old roots are removed

Media is washed and disinfected

EC and pH are corrected

Proper reuse lowers production cost significantly.

Environmental and Sustainability Impact

Compared to peat moss:

Cocopeat is renewable

Saves wetland ecosystems

Utilizes agricultural waste

Its carbon footprint is lower when sourced responsibly.

Limitations and Risk Management

Despite benefits, cocopeat has limitations:

Requires technical understanding

Poor quality products cause salinity problems

Nutrient dependency increases management responsibility

Professional results demand discipline and consistency.

Economic Perspective

Cocopeat farming:

Reduces water use by up to 60 percent

Improves yield uniformity

Enables off-season production

Supports premium-quality produce

Initial setup is higher but returns justify investment in controlled systems.

Future of Cocopeat in Global Agriculture

With rising urbanization and land pressure, cocopeat supports:

Vertical farming

Climate-resilient agriculture

Export-quality horticulture

It is becoming a global standard growing medium, not a temporary trend.

Frequently Asked Questions

Is cocopeat a complete soil replacement?

It replaces soil structurally but requires nutrient solutions.

Can cocopeat be mixed with soil?

Yes, for improved aeration and moisture control.

How long does cocopeat last?

Two to three cropping cycles with proper handling.

Is cocopeat organic?

It is natural but requires nutrient inputs for farming.

Does cocopeat attract pests?

No, when properly processed and maintained.

Final Conclusion

Cocopeat is not a shortcut or miracle solution. It is a scientific growing medium that rewards growers who understand its behavior. When managed correctly, it allows farmers to move from guesswork-based agriculture to precision-driven, sustainable production.

This foundation post sets the technical and conceptual base for all future cocopeat-focused articles. Every next post will expand on one practical dimension, building a complete global knowledge system for modern farming.

✍️Farming Writers Team

Love farming Love Farmers.

Leave a ReplyShare your thoughts: We’d love to hear your farming ideas or experiences!