Many farmers enter moringa farming after seeing one simple claim repeated everywhere: “high demand, miracle tree, export profit.” What they don’t see is how many moringa growers end up with good harvests but no serious buyers, or worse, bulk buyers who push prices so low that drying and transport cost more than the sale value.

The first loss usually doesn’t happen in the field. It happens after harvest, when farmers realise that moringa is not sold as “leaf” or “pod” in the way vegetables are sold. It is sold as quality-controlled material, and most first-time growers do not meet that standard.

A common mistake is assuming that yield equals income. Moringa can grow aggressively, even on poor land. Leaves come fast, pods form easily, and trees look healthy. That visual success hides the real question buyers ask: consistency, moisture control, contamination level, and processing discipline. Farmers who don’t plan for these from day one usually lose money even with high biomass.

Another wrong belief is that moringa leaf powder is easy money. In reality, most powder gets rejected due to colour loss, microbial count, improper drying temperature, or mixing of old and new leaves. Buyers don’t care how much you harvested. They care whether your powder matches lab parameters. One rejected batch can wipe out months of effort.

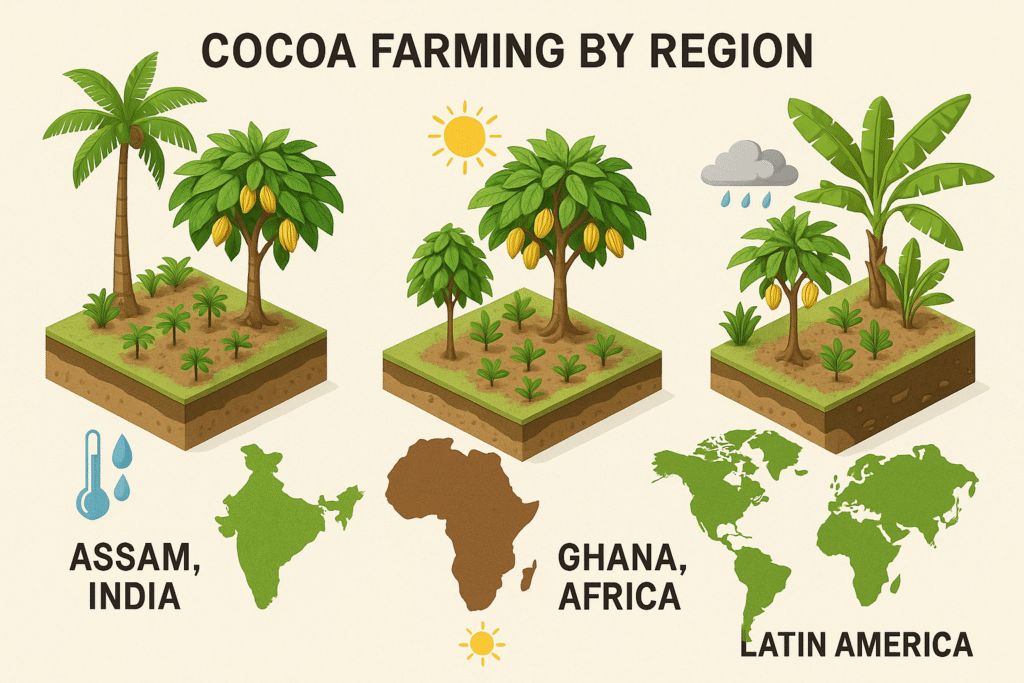

Climate suitability matters, but not in the textbook way. Moringa survives heat and drought, yes. But survival does not equal market quality. In very humid regions, leaf drying becomes a major problem. High humidity increases fungal risk and darkens leaf colour, which reduces export value sharply. Farmers in such areas often underestimate drying infrastructure cost and end up selling fresh leaves locally at vegetable prices, not medicinal prices.

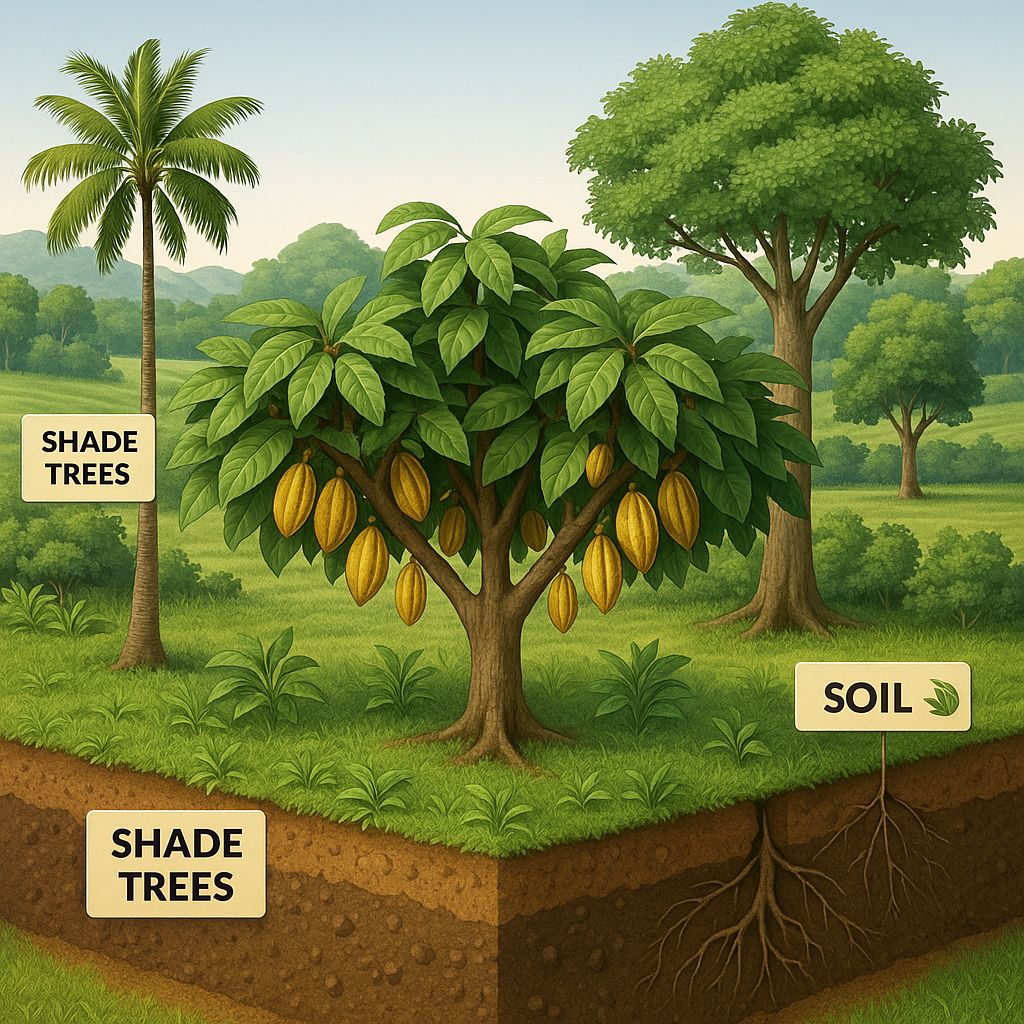

Soil fertility is another misunderstood area. Moringa grows even in poor soil, which makes people think fertilisation doesn’t matter. But nutrient imbalance directly affects leaf thickness, colour, and nutrient density. Buyers test for protein content and mineral profile. Leaves grown under nutrient stress may pass visually but fail nutritionally.

Harvest timing is where many losses quietly occur. Cutting too late reduces softness and increases fibre. Cutting too early reduces yield and increases processing cost. Most online guides skip this nuance. In real trade, harvest cycles are planned backward from buyer delivery schedules, not forward from planting date.

Processing is where moringa farming becomes either profitable or pointless. Sun-drying without temperature control causes nutrient degradation. Over-drying causes brittleness and colour loss. Under-drying causes mold. Manual sorting is labour-heavy but mandatory for export grade. Farmers who don’t calculate this labour cost beforehand often realise too late that margins are thinner than expected.

Market reality is harsh but clear. Local markets buy moringa fresh at low prices. Domestic supplement manufacturers buy only from consistent suppliers. Export buyers demand certification, batch traceability, and stable volumes. There is a big gap between “global demand exists” and “your product qualifies for it.”

Many farmers also ignore price volatility. When moringa becomes popular in a region, oversupply follows quickly. Prices crash, especially for fresh leaves. Powder prices remain stable only for certified quality. Those without processing capability suffer the most during these cycles.

This crop is not for everyone. Farmers without drying infrastructure, labour management capacity, or buyer linkage should avoid moringa despite the hype. It works best for those who think like processors, not just growers.

Moringa farming succeeds when approached as a quality manufacturing system, not a leafy crop. Those who treat it casually often exit quietly after one or two seasons.

TOP 10 FAQ – REAL QUESTIONS FARMERS ASK AFTER LOSSES

Is moringa farming really profitable for small farmers?

Only if processing and buyer linkage are planned before planting. Without that, profits are usually low.

Why do buyers reject moringa leaf powder?

Most rejections happen due to moisture, colour degradation, or microbial contamination.

Is fresh moringa leaf selling sustainable?

Only for local vegetable markets. It does not generate medicinal-grade margins.

Does moringa grow in all climates equally?

It grows everywhere, but quality differs sharply with humidity and soil balance.

Is organic moringa easier to sell?

Organic helps, but certification and consistency matter more than labels.

How often should moringa be harvested for best quality?

Harvest timing must match buyer quality standards, not just plant growth speed.

What is the biggest hidden cost in moringa farming?

Labour during sorting, drying, and quality control.

Can moringa pods be more profitable than leaves?

Only in specific fresh markets. Export demand is stronger for leaf products.

Is moringa a good crop for beginners?

Not unless they understand processing and quality management.

When should a farmer avoid moringa completely?

When there is no drying facility, no buyer contract, and no quality testing access.

✍️Farming Writers Team

Love farming Love Farmers

Read A Next Post 👇

https://farmingwriters.com/goat-farming-profit-risks-and-market-reality/