Across the world, farmers buy “good quality cocopeat” and still lose crops within weeks. Leaves burn, roots turn brown, growth stalls, and no fertilizer seems to fix it. Sellers blame water. Advisors blame nutrients. The real problem usually starts much earlier.

Cocopeat is not ready when it looks clean. It is not safe when it feels light. And it is not suitable just because it is branded.

Most cocopeat-related crop failures are not caused by farmers. They are caused by incomplete preparation and incorrect buffering steps almost never explained honestly.

This post explains what actually happens inside cocopeat before crops ever touch it.

Raw Cocopeat vs Usable Cocopeat: A Critical Difference

Raw cocopeat comes directly from coconut husk processing. At this stage, it contains:

Excess potassium

High sodium salts

Unstable electrical conductivity

Active ion-exchange sites

Plant roots entering raw cocopeat face chemical stress even if water and fertilizer are perfect.

Usable cocopeat is cocopeat that has been washed, buffered, stabilized, and tested. Anything less is a gamble.

The Potassium Trap: Why Plants Starve in Cocopeat

Coconut husk naturally stores potassium. This potassium occupies exchange sites inside cocopeat fibers.

When calcium or magnesium fertilizer is added:

Cocopeat absorbs Ca and Mg

Releases potassium into solution

Roots receive excess K

Calcium deficiency symptoms appear

This is why farmers see:

Blossom end rot

Weak stems

Leaf edge burn

Poor fruit quality

No amount of extra calcium fixes this unless cocopeat is buffered correctly.

What Buffering Actually Means (Not the Marketing Version)

Buffering is not soaking cocopeat in water.

True buffering means:

Replacing excess potassium and sodium

Saturating exchange sites with calcium

Stabilizing ion exchange behavior

This is done using controlled calcium solutions, specific contact time, and multiple washes.

Skipping or rushing this step creates invisible problems that appear later in the crop cycle.

Why Simple Washing Is Not Enough

Many producers only wash cocopeat to reduce EC. This removes surface salts but does not fix internal exchange imbalance.

As a result:

Initial EC looks acceptable

Crop starts well

Failure appears after 2–4 weeks

Farmers wrongly assume disease or fertilizer error, while the root cause was present from day one.

Quality Grades That Are Never Explained

Low-Grade Cocopeat

High sodium

Poor washing

No buffering

Short fiber breakdown

Used mostly where price matters more than performance.

Medium-Grade Cocopeat

Washed

Partially buffered

Inconsistent batches

Risky for high-value crops.

Professional-Grade Cocopeat

Fully buffered

Batch-tested

Stable EC and pH

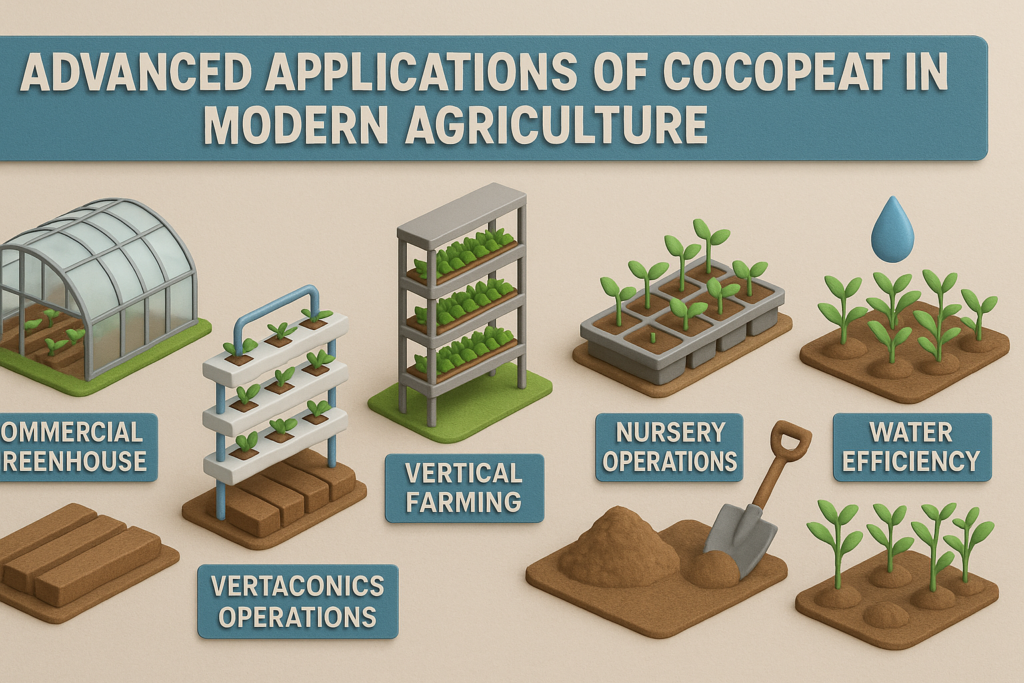

Used by export nurseries and commercial greenhouses.

EC and pH Reality Before Planting

Professional growers never trust labels. They test.

Target ranges before planting:

EC: Stable and low

pH: Neutral to slightly acidic

Unstable readings mean cocopeat is still chemically active and unsafe.

Why Rehydration Method Changes Performance

Compressed cocopeat blocks expand unevenly if water quality and method are wrong.

Common mistakes:

Using saline water

Incomplete expansion

Uneven moisture zones

This creates dry pockets, salt concentration zones, and root stress.

Correct rehydration is slow, uniform, and controlled.

Storage Mistakes That Ruin Cocopeat

Even well-processed cocopeat degrades when:

Stored in open rain

Exposed to contamination

Left anaerobic for long periods

Microbial imbalance develops, increasing disease risk.

Why Farmers Think Cocopeat “Stops Working”

Cocopeat does not fail suddenly. It degrades gradually.

Reasons include:

Fiber breakdown

Salt accumulation

Root residue buildup

Collapsed pore structure

Ignoring lifespan leads to repeat crop failures.

Professional Handling Practices Worldwide

Successful growers:

Source consistent suppliers

Demand buffering data

Test every batch

Define reuse limits

Never mix old and new cocopeat blindly

This discipline separates profit from loss.

Decision Checklist Before Using Cocopeat

Use cocopeat only if:

Buffering is confirmed

EC and pH are tested

Water quality is suitable

Avoid cocopeat if:

Source transparency is missing

Price is the only advantage

No monitoring is possible

Final Conclusion

Cocopeat preparation is not a formality. It is the foundation. Most failures blamed on nutrients, disease, or climate are actually chemical mistakes locked inside the growing media.

Cocopeat rewards preparation. It punishes shortcuts.

In the next post of this series, we will go deeper into irrigation strategy and fertigation design in cocopeat systems, where most operational losses occur.

✍️Farming Writers Team

Love farming Love Farmers.

Read A Next Post 👇

https://farmingwriters.com/advanced-applications-of-cocopeat-global-agriculture-guide/