Cocopeat farming fails not because cocopeat is a poor medium, but because nutrient management is misunderstood or underestimated. Unlike soil, cocopeat does not supply nutrients on its own. It acts as a controlled root-support system, entirely dependent on what the grower provides.

In soil farming, nutrient errors are partially buffered by soil reserves. In cocopeat farming, every nutritional mistake appears directly and quickly in plant growth. This makes nutrient management in cocopeat both a challenge and an opportunity: mistakes are costly, but correct management delivers exceptional yield consistency.

This post explains complete nutrient science and practical application for cocopeat growers worldwide.

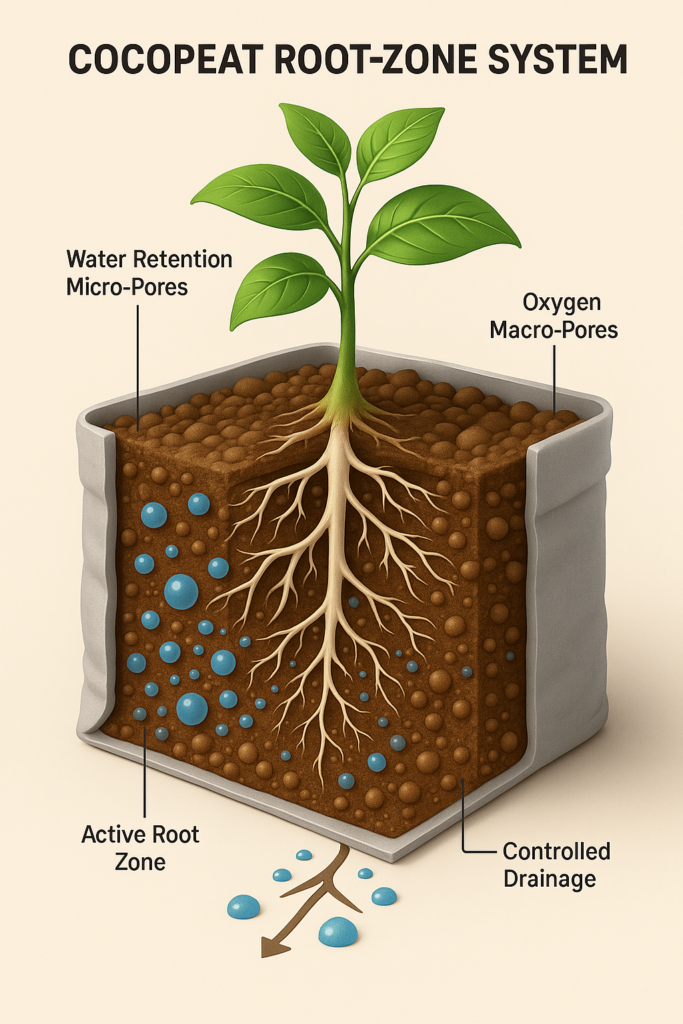

Understanding Cocopeat as a Nutrient Medium

Cocopeat is:

Structurally supportive

Chemically semi-inert

Nutrient-poor by nature

Key nutritional reality:

Almost zero nitrogen and phosphorus

Naturally high potassium

Requires continuous external feeding

Thus, cocopeat farming is essentially a fertigation-driven production system.

Difference Between Soil Nutrition and Cocopeat Nutrition

Soil-Based Feeding

Nutrients stored in soil particles

Slow release

High margin for error

Cocopeat-Based Feeding

Nutrients dissolved in irrigation water

Immediate root availability

Low margin for error

This difference explains why fertilizer formulas designed for soil often fail in cocopeat systems.

The Role of Fertigation in Cocopeat

Fertigation is the process of delivering nutrients through irrigation water. In cocopeat farming:

All nutrients are supplied via fertigation

Uniform distribution is essential

EC and pH must be monitored constantly

A stable fertigation program determines plant health, yield, and quality.

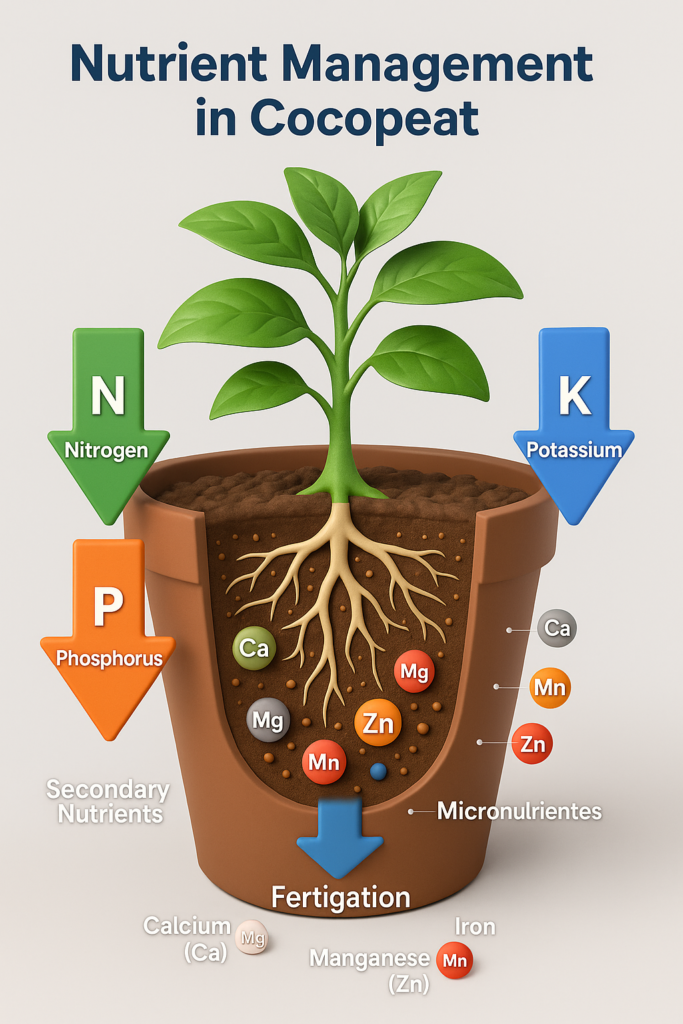

Essential Macronutrients in Cocopeat

Nitrogen (N)

Function:

Leaf growth

Chlorophyll production

Management:

Supplied continuously in small doses

Excess causes soft growth and disease sensitivity

Phosphorus (P)

Function:

Root development

Flower initiation

Management:

Moderate supply required

Overuse blocks micronutrients

Potassium (K)

Function:

Fruit quality

Water regulation

Special note:

Cocopeat already contains potassium

External potassium must be carefully balanced

Secondary Nutrients: Calcium and Magnesium

Calcium (Ca)

Role:

Cell wall strength

Root tip growth

In cocopeat:

Most critical nutrient

Deficiency common if buffering or supply is inadequate

Magnesium (Mg)

Role:

Chlorophyll center

Energy transfer

Importance:

Often suppressed by excess potassium

Balanced Ca:Mg ratio is essential for long-term success.

Micronutrients in Cocopeat

Although required in small amounts, micronutrients control crop performance.

Key micronutrients:

Iron

Manganese

Zinc

Copper

Boron

Molybdenum

In cocopeat systems:

Deficiencies appear faster

Overdosing causes toxicity quickly

Chelated forms are recommended for stability.

Ideal pH and EC for Nutrient Uptake

pH Range

Optimal: 5.8 – 6.5

Effects:

Low pH locks calcium and magnesium

High pH blocks iron and zinc

EC Range

Varies by crop and stage:

Seedling stage: Low EC

Vegetative growth: Moderate EC

Fruiting stage: Higher EC

Regular monitoring is mandatory.

Designing a Cocopeat Fertigation Schedule

Seedling Stage

Low EC

Balanced nutrients

Focus on root establishment

Vegetative Stage

Higher nitrogen supply

Stable calcium availability

Strong leaf development

Flowering and Fruiting Stage

Reduced nitrogen

Increased potassium

Stable calcium for fruit quality

Crop stage-specific feeding is non-negotiable.

Common Nutrient Deficiencies in Cocopeat

Calcium Deficiency

Symptoms:

Leaf tip burn

Blossom-end rot

Causes:

Skipping buffering

High potassium

Magnesium Deficiency

Symptoms:

Yellowing between leaf veins

Cause:

Excess calcium or potassium

Iron Deficiency

Symptoms:

Yellow new leaves

Cause:

High pH or poor chelation

Understanding symptom patterns prevents panic reactions.

Correcting Nutrient Problems

Principles:

Identify cause before applying fertilizer

Correct pH before adding nutrients

Reduce EC if stress symptoms appear

Blind fertilizer application worsens problems in cocopeat.

Organic Nutrient Management in Cocopeat

Possible but challenging:

Requires controlled liquid organic nutrients

Solid organic matter should be minimal

Microbial balance must be monitored

Organic cocopeat systems demand advanced management.

Reusing Cocopeat and Nutrient Considerations

When reusing:

Residual salts accumulate

Nutrient profile shifts

EC must be reset

Reused cocopeat requires revised nutrient strategy.

Economic Impact of Proper Nutrient Management

Correct nutrient management:

Maximizes fertilizer efficiency

Reduces waste

Improves uniformity

Increases market-grade yield

Poor management:

Creates unseen losses

Reduces crop lifespan

Nutrition is the largest controllable cost in cocopeat farming.

Global Best Practices

Professional growers:

Monitor EC and pH daily

Use crop-stage-specific formulations

Maintain detailed fertigation records

Consistency, not complexity, defines success.

Frequently Asked Questions

Is general NPK enough for cocopeat?

No. Balanced macro and micro nutrients are required.

Can soil fertilizers be used?

Only if fully soluble and correctly balanced.

How often should nutrients be applied?

With every irrigation in controlled systems.

Is nutrient burn possible?

Yes. Cocopeat systems react immediately to excess.

Does buffered cocopeat eliminate calcium need?

No. Buffering reduces loss, not supply requirement.

Final Conclusion

Nutrient management in cocopeat farming is not guesswork or shortcut-based agriculture. It is a precision-driven feeding system where success depends on understanding how nutrients interact with water, roots, and cocopeat chemistry.

Growers who master nutrient management unlock:

Higher yield

Better quality

Greater predictability

Long-term system sustainability

This post completes the nutritional foundation of cocopeat farming and prepares the ground for crop-specific and advanced system-level guides.

✍️Farming Writers Team

Love farming Love Farmers.

Read A Next Post 👇

https://farmingwriters.com/cocopeat-block-preparation-step-by-step-guide/