Rice Plant Distance: Why Overcrowded Paddy Looks Fine but Sells Cheap

Rice failures usually arrive after harvest, not before it.

The crop stands tall.

Panicles appear full.

The field looks successful.

Yet, when the lot reaches milling or mandi, the story changes: more broken grains, poor head rice recovery, weak test weight.

The damage traces back to a quiet early decision plant distance during transplanting.

The Assumption That Pushes Farmers Into Trouble

Many farmers believe:

Closer transplanting means more panicles, so more yield

This belief survives because:

Early vegetative growth looks strong

Tiller counts increase

The field closes canopy fast

But rice is not sold by hill count.

It is sold by grain recovery, grain strength, and uniform filling.

Close spacing shifts the problem from the field to the mill.

Why Rice Suffers From Crowding More Than It Shows

When rice hills are too close:

Tillers compete unevenly

Panicles emerge underfed

Grain filling time shortens

The plant completes its life cycle.

But grains:

Remain lighter

Break easily during milling

Reduce head rice percentage

These losses don’t show at harvest.

They show at payment.

Market & Milling Reality Farmers Often Miss

Millers and buyers focus on:

Head rice recovery

Broken percentage

Uniform grain length

Dense planting often results in:

More chalky grains

Higher breakage

Lower milling returns

Even a 2–3% drop in head rice recovery can erase profits from an entire season.

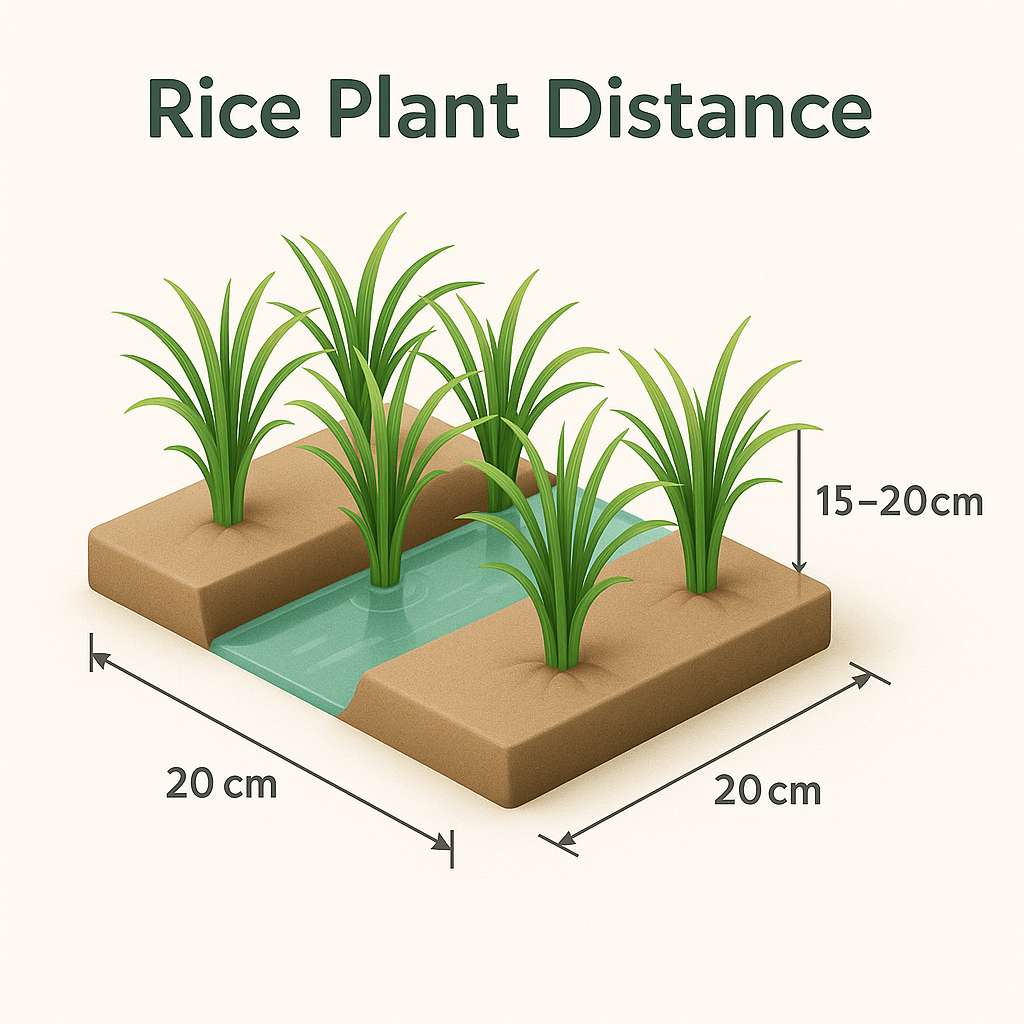

Safe Open-Field Rice Spacing (Transplanted Paddy)

This distance is not designed to “maximize tillers.”

It is designed to stabilize grain filling.

Commercial Safe Spacing

Row to row: 20 cm

Plant to plant: 15–20 cm

Seedlings per hill: 2–3 only

This range allows:

Balanced tiller development

Better light interception

Stronger grain structure

Where Close Rice Spacing Fails the Fastest

Loss risk rises sharply when:

Nitrogen use is high

Cloudy or humid weather extends

Fields remain waterlogged continuously

In these cases, dense spacing:

Encourages soft straw

Reduces assimilate flow to grains

Increases lodging and breakage

Farmers often blame fertilizer or weather.

Spacing made the damage irreversible.

SRI and Wide Spacing: Not for Everyone

Wide spacing systems promise miracles, but reality is mixed.

They fail when:

Weed pressure is unmanaged

Labour for line transplanting is unavailable

Fields cannot maintain proper water control

Distance is not magic.

It only works when management can support it.

Rice Hills per Acre: A Reality Window

With standard spacing (20 × 20 cm):

Hills per acre fall into a balanced range

Tillering compensates naturally

Grain filling remains uniform

Chasing extreme hill counts usually creates yield illusion with quality loss.

Repeating Distance Errors in Rice Farming

Using 4–5 seedlings per hill to “ensure stand”

Reducing spacing to hide poor nursery quality

Keeping fields flooded continuously in dense crops

Copying SRI spacing without management capacity

These mistakes don’t reduce yield immediately.

They reduce payment.

Decision Check Before Transplanting

If your selling channel:

Penalizes broken grains → avoid dense spacing

Depends on milling recovery → protect grain filling

Pays by quality, not weight → spacing discipline matters

Distance decides grain integrity, not just plant count.

Final Judgment

Rice spacing should protect what the buyer pays for, not what the field displays.

An overcrowded paddy can look perfect and still sell cheap.

Once grains are weak, no practice can fix them later.

Plant distance is not a layout choice.

It is a value-protection decision made on transplanting day.

✍️Farming Writers Team

Love farming Love farmers

Read A Next Post 👇

Leave a ReplyShare your thoughts: We’d love to hear your farming ideas or experiences!