Introduction: Why Garlic Needs a Different Packaging Approach

Garlic is a low-moisture but long-storage crop. It looks hardy, but incorrect packaging and storage quickly lead to:

Mold growth

Clove dehydration

Weight shrinkage

Yellowing or sprouting

Strong odor contamination

Export rejection

Unlike soft vegetables, garlic profit comes from curing quality, airflow control, and long-term storage discipline, not heavy protection. Proper packaging allows farmers to sell garlic months after harvest, often at much higher prices.

- Core Principles of Garlic Packaging

Garlic packaging must follow four rules:

Maximum ventilation

Zero moisture trapping

Light protection

Odor isolation

Any packaging that traps humidity or heat destroys garlic value faster than poor yield.

- Garlic Packaging Material System

3.1 Primary Contact Packaging (Clove Safety Layer)

Best materials:

Open mesh netting

Natural fiber net

Loose hanging bunches (traditional curing phase)

Avoid completely:

Plastic liners

Sealed poly bags

Non-ventilated sacks

Garlic skins act as natural protection; airflow is more important than cushioning.

3.2 Secondary Packaging (Main Holding Units)

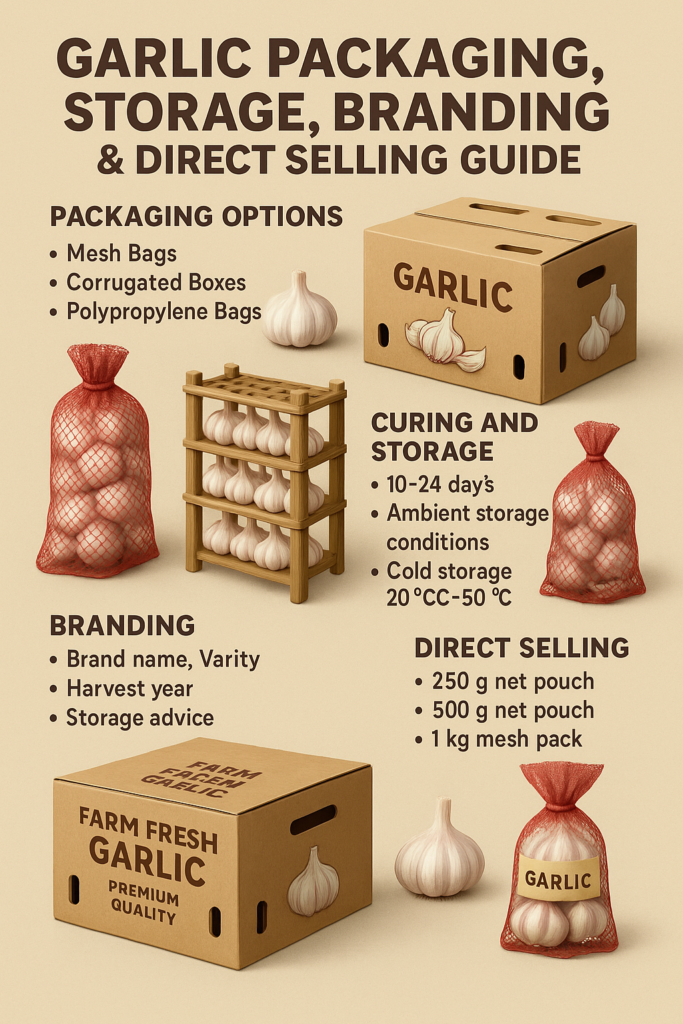

A. Mesh Bags (Industry Standard)

Most widely used worldwide.

Common sizes:

1 kg

5 kg

10 kg

20 kg

25 kg

Benefits:

Excellent airflow

Easy inspection

Reduced fungal risk

Low-cost and reusable

Used for:

Wholesale

Storage

Export transport

B. Woven Polypropylene Bags (Only for Short Transport)

Used when:

Strong stacking is required

Transport duration is short

Limitation:

Less airflow than mesh

Must not be used for long storage

C. Corrugated Ventilated Boxes (Retail & Premium Markets)

Used for:

Supermarkets

Export retail

Direct-to-consumer sales

Specifications:

5-ply corrugated board

Side ventilation slots

Weight limits: 3 kg, 5 kg, 10 kg

Low-ink printing

- Garlic Grading System

Grading improves price and reduces storage loss.

Grade A – Premium Market & Export

Large uniform bulbs

Tight, dry outer skin

No sprouting

No mold spots

Grade B – General Retail

Medium bulbs

Slight size variation

Grade C – Processing

Small bulbs

Loose skin

Minor visual defects

Grading must be done after curing but before storage.

- Garlic Curing Process (Very Critical)

Curing determines garlic shelf life.

Curing Method

Duration: 10–20 days

Environment: Dry, shaded, well-ventilated

Method: Hanging bunches or thin layers on racks

Curing Objectives

Reduce moisture

Harden skins

Seal neck tissue

Prevent mold growth

Poor curing = guaranteed storage failure.

- Scientific Garlic Storage System

Garlic storage can be ambient or cold, based on market strategy.

Ambient Storage

Temperature: 20–25°C

Humidity: 60–70%

Strong airflow

Dark conditions

Cold Storage (Long-Term Strategy)

Temperature: 0–2°C

Humidity: 65–70%

Controlled ventilation

Cold storage is used for price timing and export control, not basic storage.

- Transport Guidelines

Garlic transport must avoid moisture and compression.

Rules:

Use ventilated vehicles

Keep produce dry at all times

Avoid rain exposure

Do not mix with high-moisture crops

Avoid plastic covers during transit

- Retail Display Standards

Retail garlic quality depends on dryness.

Display guidelines:

Open baskets or ventilated crates

No misting

Low-intensity lighting

Dry environment

Moisture exposure at retail immediately reduces shelf life.

- Branding Strategy for Garlic Farmers

Branding garlic is highly effective in retail and export markets.

Branding Elements

Clean brand name

Garlic variety (local / jumbo / export grade)

Net weight

Harvest year

Storage advice

QR code for traceability

Design Philosophy

Minimal

Natural colors

Low ink coverage

Clear text

Over-designed packaging increases mold risk.

- Direct Selling & Marketing Models

10.1 Retail Packs

250 g net pouch

500 g net pouch

1 kg mesh pack

10.2 Institutional Sales

Restaurants

Food processors

Pickle manufacturers

Packaging:

10–25 kg mesh bags

10.3 Export Selling

Uniform grading

Strong mesh bagging

Moisture records

Traceability labels

Export garlic packaging must strictly meet airflow standards.

- Packaging Cost Structure

Packaging TypeApprox Cost25 kg mesh bag₹15–2510 kg mesh bag₹8–121 kg net pouch₹2–45 kg corrugated box₹20–30

Packaging cost is low, but mistakes are expensive.

- Frequently Asked Questions

Q1. Can garlic be stored in plastic bags?

No. Plastic causes moisture buildup and fungal growth.

Q2. Is cold storage necessary for garlic?

Only for long-term price-based selling.

Q3. Why is curing more important than packaging?

Without curing, no packaging will prevent spoilage.

Q4. Does branding really help in garlic sales?

Yes, especially in retail and export markets.

Q5. Can garlic be sold directly to consumers?

Yes, small net packs sell well in local and urban markets.

- Conclusion

Garlic packaging is not about heavy protection; it is about air, dryness and discipline. Farmers who invest time in proper curing, airflow-based packaging and scientific storage consistently outperform those who rush garlic to market. Branding further upgrades garlic from a bulk commodity to a traceable, retail-ready product. With the right post-harvest system, garlic becomes one of the safest and most profitable storage crops for farmers.

✍️Farming Writers Team

Love Farming Love Farmers

Read A Next Post 👇