Opening: When Technology Takes Control Away From the Field

Rice quality is grown in fields, but it is defined inside machines.

Once rice enters a mill, natural attributes like soil quality, cultivation care, and harvest discipline stop mattering as much.

From that point onward, polishing machines decide what the rice becomes, how it is priced, and who earns from it.

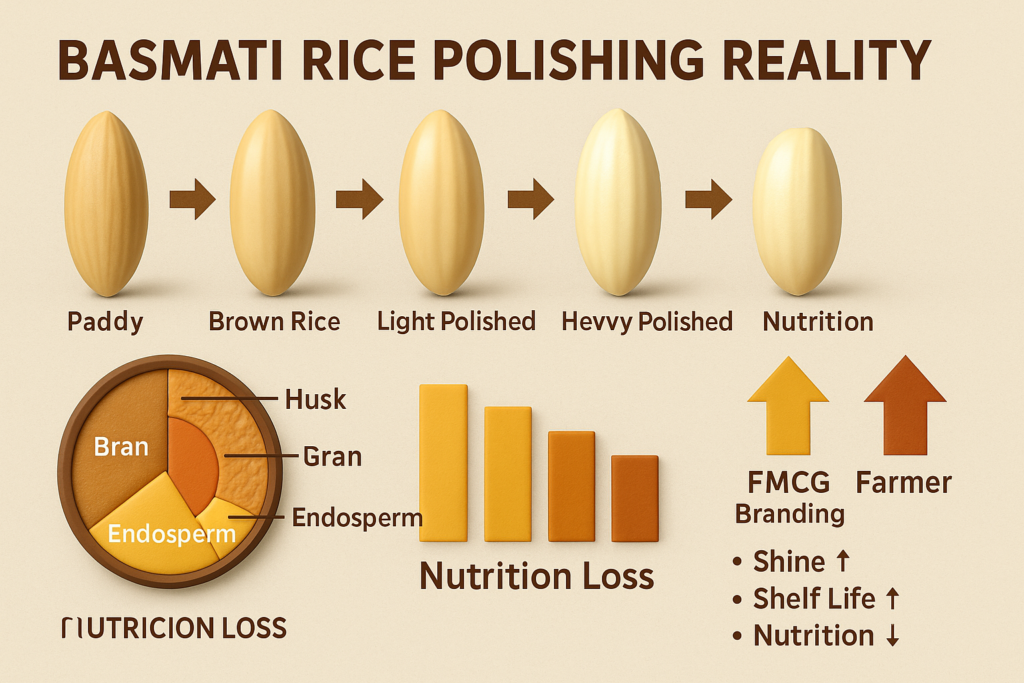

Most people think polishing is a single step.

In reality, it is a chain of specialized machines, each designed not to improve food—but to control market outcomes.

Rice Polishing Is a Machine System, Not a Single Process

Modern rice processing uses a sequence of machines, each with a specific commercial purpose:

Husk removal machines

Whitening machines

Silky polish machines

Grading and separation systems

Each stage removes something different:

Physical layers

Visual defects

Farmer differentiation

Market risk

The more advanced the machine chain, the further rice moves from its agricultural identity.

Dehusking Machines: Where Identity First Breaks

Dehusking machines remove the outer husk and convert paddy into brown rice.

This stage:

Does not reduce nutrition

Does not increase value

Does not change market price directly

But it standardizes rice, making all batches visually similar regardless of how they were grown.

This is the first step where field-level differences disappear.

Whitening Machines: Where Value Extraction Begins

Whitening machines use abrasive surfaces to remove bran layers.

These machines:

Decide how much natural layer is removed

Control breakage percentage

Directly affect recovery ratio

A small adjustment in pressure can:

Increase shine

Reduce weight

Increase broken grain output

This is where machine settings silently transfer value:

Less weight → loss for farmer

More uniform grains → gain for processor

Silky Polishing Machines: The Illusion Creators

Silky polish machines do not remove much material.

They rearrange surface appearance.

They:

Smooth grain surface

Seal micro-cracks

Increase reflectivity

These machines exist for one reason: to make rice look premium without adding substance.

Silky polishing increases:

Brand appeal

Export acceptance

Visual trust

But it does not improve nutrition, safety, or taste.

Machine Control vs Grain Damage

High-speed machines increase throughput but also:

Increase grain breakage

Generate heat stress

Reduce internal grain strength

Broken grains are:

Recycled into cheaper channels

Used in secondary products

Often hidden through blending

Machines allow processors to control loss visibility, not loss itself.

Why Milling Machines Favor Processors, Not Farmers

Farmers are paid by weight and grade at purchase.

Machines control:

Final recovery

Market segmentation

Price positioning

A processor with advanced machines can:

Split one batch into multiple product categories

Sell visually different rice from the same input

Multiply margins without improving agriculture

Technology concentrates power upward.

Standardization: The Hidden Goal of Polishing Machines

Global markets demand:

Uniform grain color

Predictable cooking

Minimal defects

Polishing machines are designed to eliminate variation, not preserve origin.

Standardization helps:

Logistics

Branding

Export contracts

But it removes:

Local identity

Farming story

Natural diversity

Why Small Mills Cannot Compete With Large Machine Chains

Small mills lack:

Precision control

Advanced polishers

Automated grading

As a result:

Their rice looks inconsistent

Their market access shrinks

Their pricing power collapses

Technology does not just process rice.

It decides who survives in the market.

Can Technology Ever Work for Farmers?

Yes—but only if:

Farmers control milling

Processing transparency exists

Market rewards honesty over shine

Without ownership, machines remain tools of extraction, not empowerment.

The Long-Term Risk of Machine-Dominated Processing

As machines optimize for appearance:

Nutrition becomes secondary

Origin becomes irrelevant

Farmers become raw material suppliers

Rice turns from food into format.

This is efficient—but fragile.

Final Conclusion: Rice Is No Longer Shaped by Soil Alone

Rice polishing machines do more than clean grain.

They redesign food to fit markets, logistics, and branding.

Once rice enters these machines:

Farming value pauses

Processing value accelerates

Understanding these machines is critical for anyone who grows, processes, sells, or regulates rice.

Because in the modern system,

the final identity of rice is not grown—it is engineered.

✍️Farming Writers Team

Love farming Love Farmers.

Read A Next Post 👇

https://farmingwriters.com/rice-polishing-levels-market-value/

https://farmingwriters.com/polished-vs-unpolished-rice-reality/